+94 77 228 1006

softprintingsolutions@gmail.com

+94 77 228 1006

softprintingsolutions@gmail.com

Digital Printing

Offset Printing

24/7 Services

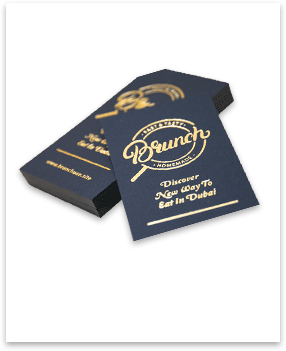

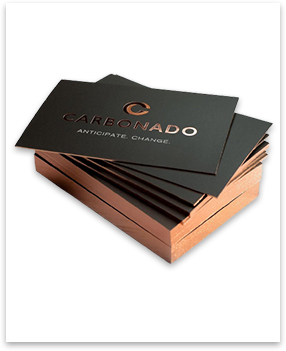

Foiling in printing is a specialized and visually striking technique used to enhance printed materials. It involves applying a metallic or colored foil onto paper or other substrates to create eye-catching, shiny, and reflective elements. Foiling is often used for adding a touch of elegance, luxury, or distinction to various printed items such as business cards, invitations, packaging, and promotional materials. This process can be done through hot foil stamping, where a heated die is used to transfer the foil onto the material, or cold foil printing, where an adhesive is applied to the substrate before the foil is pressed onto it. Foiling not only adds a tactile and aesthetic dimension to printed designs but also helps them stand out and leave a lasting impression on the viewer

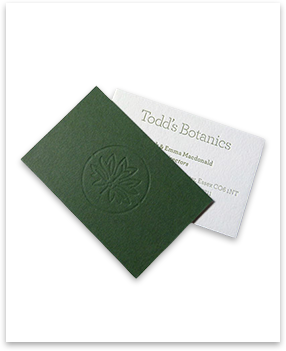

Embossing in printing is a decorative technique that adds texture and dimension to printed materials. It involves raising certain portions of the paper or other printing substrate to create a three-dimensional effect. This is achieved by using a combination of heat and pressure to press a metal die or engraved plate onto the material, which results in raised or indented areas that stand out visually and can be felt when touched. Embossing is commonly used in various printed materials, such as business cards, stationery, packaging, and invitations, to enhance their visual appeal and tactile quality, making them more engaging and memorable to the recipient. This technique is often combined with other printing methods, such as foil stamping or debossing, to create striking and distinctive designs.

Embossing and debossing are both techniques used in the field of printing and graphic design to create three-dimensional effects on paper or other materials. While embossing raises a design or pattern above the surface, debossing does the opposite by pressing it into the material, creating a depressed or indented effect. Debossing is achieved by using a die or engraved plate to apply pressure and leave a lasting impression on the material, resulting in a visually appealing and tactile enhancement to printed materials such as business cards, invitations, packaging, and more. This technique adds depth and texture to the design, making it a popular choice for adding a touch of elegance and sophistication to various printed products.

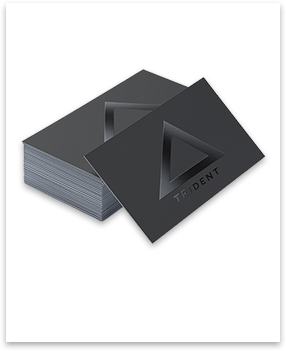

UV spot varnish printing is a specialized printing technique that adds a layer of glossy or matte coating to specific areas of a printed material, creating a striking contrast between the varnished and non-varnished areas. This process uses ultraviolet (UV) light to cure the varnish instantly, resulting in a smooth and raised finish. UV spot varnish is often employed to enhance the visual appeal of printed materials such as business cards, brochures, packaging, and promotional materials, giving them a luxurious and eye-catching appearance while also providing protection against wear and tear. This technique is popular for its ability to accentuate key elements, add texture, and elevate the overall quality of printed products, making them more attractive and memorable to the audience.

Laminations in printing refer to the process of applying a thin protective layer, often made of plastic film, to the surface of printed materials. This layer, known as lamination, serves multiple purposes, including enhancing the durability and longevity of printed items while also improving their appearance. By encasing printed documents or images within a lamination film, they become resistant to moisture, stains, tearing, and fading, making them more robust and long-lasting. Lamination is commonly used in various printing applications, such as posters, ID cards, labels, menus, and other items where protection and an attractive finish are essential. This process not only safeguards printed materials but also adds a professional touch, making them more visually appealing and tactilely pleasing.

Gloss lamination in printing is a popular finishing technique used to enhance the appearance and durability of printed materials. It involves applying a thin layer of glossy film or coating to the surface of printed items, such as brochures, posters, business cards, and packaging. This process not only gives the printed piece a shiny, reflective finish but also provides several benefits,

Gloss lamination adds a polished and professional look to printed materials. The high shine and reflective surface can make colors appear more vibrant and text more readable, which is especially effective for photos and graphics.

The glossy film serves as a protective barrier, safeguarding the printed piece from wear and tear, moisture, and fading. This extends the life of the printed materials, making them more resilient and long-lasting.

Gloss lamination can help smooth out imperfections in the printed surface, resulting in a smoother and more consistent finish. This is particularly beneficial for high-quality images and designs.

Depending on the thickness of the glossy coating, it can add a tactile dimension to the printed item, making it feel smoother and more substantial to the touch.

Many businesses use gloss lamination to elevate their brand image. The shiny finish conveys a sense of quality and attention to detail, leaving a lasting impression on customers and clients.

Overall, gloss lamination is a versatile and effective technique in the world of printing, offering both aesthetic and functional advantages that can make printed materials more appealing and durable.

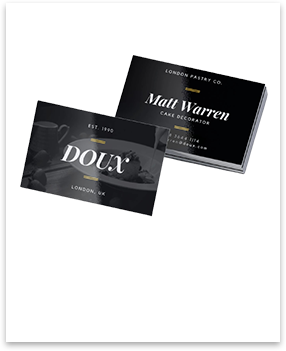

Matt lamination is a popular finishing technique in the world of printing and graphic design. It

involves applying a thin layer of matte or non-glossy film onto the surface of printed

materials, such as brochures, posters, book covers, or business cards. This lamination process

not only enhances the aesthetics of the printed piece but also provides several practical

benefits.

Matt lamination gives printed materials a smooth and elegant matte finish, which can reduce

glare and create a more subdued, sophisticated appearance. It not only enhances the visual

appeal but also adds a layer of protection, making the printed items more durable and resistant

to wear and tear. This makes them less prone to scratches, fingerprints, and moisture damage,

increasing their longevity.

Overall, Matt lamination is a valuable tool in the world of printing, offering both aesthetic

and functional advantages for a wide range of printed materials, leaving them not only looking

great but also standing up to the rigors of everyday use.

Velvet lamination is a specialized finishing technique commonly used in the printing industry to

enhance the appearance and tactile quality of printed materials. It involves the application of

a thin, soft, and velvetytextured film onto the surface of paper or other substrates. This

process not only adds a luxurious and premium feel to the printed piece but also provides

several practical benefits.

Velvet lamination offers a smooth and matte finish that reduces glare and adds a sophisticated

touch to printed items such as brochures, business cards, book covers, packaging, and

promotional materials. The soft, tactile sensation created by the velvet texture makes these

materials more engaging to touch, leaving a lasting impression on the recipient.

Furthermore, aside from its aesthetic appeal, velvet lamination also provides protection against

wear and tear, making printed materials more durable and long-lasting. It helps guard against

scratches, scuffs, and moisture, extending the lifespan of the printed piece.

In summary, velvet lamination is a versatile and appealing finishing option in the world of

printing, combining both aesthetic and practical advantages to elevate the quality and impact of

printed materials.

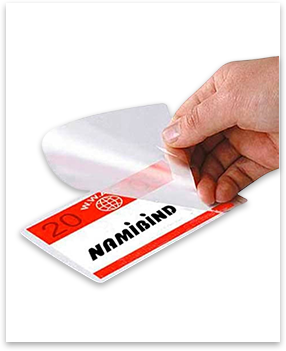

Hard lamination in printing refers to a finishing technique used to enhance the durability, appearance, and protection of printed materials. It involves applying a thin layer of transparent plastic film, often made of materials like polyester or polypropylene, onto the surface of printed items such as posters, business cards, book covers, or packaging. This lamination process not only adds a glossy or matte finish to the printed piece but also provides a protective barrier against wear and tear, moisture, and fading. Hard lamination can significantly improve the longevity and overall quality of printed materials, making them more appealing and resilient in various applications, from marketing collateral to product packaging.

Plastic

lamination in printing is a process that involves covering printed materials, such as posters,

business cards, or packaging, with a thin layer of plastic film. This protective layer serves

multiple purposes, including enhancing the appearance of the printed piece, increasing its

durability, and safeguarding it against wear and tear.

Plastic lamination is achieved by applying a transparent or matte plastic film onto the surface

of the printed material using specialized laminating equipment. This process not only provides a

polished and professional finish but also helps to protect the print from moisture, UV rays, and

everyday handling, extending its lifespan and maintaining its vibrant colors.

Whether used for marketing materials, educational resources, or product packaging, plastic

lamination plays a crucial role in preserving the visual appeal and integrity of printed

materials, making them more resilient and long-lasting in various applications.

Please provide the needed information for your order.